Automotive Supply Chain Demystified

Mia Wilson

Photo: Automotive Supply Chain Demystified

The automotive industry is one of the most complex and dynamic sectors in the global economy. Central to its operation is the automotive supply chain, a vast and intricate network that connects raw material suppliers, manufacturers, distributors, and retailers to deliver vehicles to consumers. Despite its significance, the automotive supply chain remains a mystery to many. This article will unravel the complexities of this essential system, providing a clear understanding of its components, challenges, and future trends.

Understanding the Automotive Supply Chain

At its core, the automotive supply chain is a sequence of processes and stakeholders involved in producing and delivering vehicles. It includes several key stages:

- Raw Material Procurement: The journey begins with sourcing raw materials such as steel, aluminum, rubber, and plastics. These materials are essential for manufacturing various vehicle components.

- Component Manufacturing: Tier 1 and Tier 2 suppliers transform raw materials into components like engines, transmissions, tires, and electronic systems.

- Assembly: Original Equipment Manufacturers (OEMs) assemble these components into finished vehicles at production plants.

- Distribution: Finished vehicles are transported to dealerships via a network of logistics providers.

- Retail: The final step involves selling vehicles to consumers through dealerships or online platforms.

Challenges in the Automotive Supply Chain

1. Globalization and Complexity

The automotive supply chain spans multiple countries, making it vulnerable to geopolitical events, trade tariffs, and customs regulations. For example, a disruption in semiconductor production in Asia can delay vehicle manufacturing globally.

2. Supply Chain Disruptions

Natural disasters, pandemics, and political unrest can create bottlenecks. The COVID-19 pandemic is a recent example, causing unprecedented delays and exposing vulnerabilities in just-in-time (JIT) manufacturing.

3. Rising Costs

Fluctuations in raw material prices and increased labor costs have significantly impacted the profitability of supply chain operations.

4. Sustainability Pressure

Governments and consumers are demanding greener production practices, pushing automakers to source materials ethically and reduce carbon emissions across the supply chain.

Innovations Shaping the Future of Automotive Supply Chains

1. Digital Transformation

Technologies such as artificial intelligence (AI), the Internet of Things (IoT), and blockchain are revolutionizing supply chain management. AI-powered forecasting tools improve demand predictions, while blockchain ensures transparency and traceability in sourcing.

2. Electrification

The shift toward electric vehicles (EVs) is transforming supply chain dynamics. EVs require batteries made from rare materials like lithium and cobalt, driving the need for specialized sourcing and logistics solutions.

3. 3D Printing

Additive manufacturing allows for on-demand production of complex parts, reducing the need for large inventories and minimizing lead times.

4. Sustainability Initiatives

OEMs are adopting circular economy principles, such as recycling vehicle components and reducing waste. Companies like Toyota and BMW are leading efforts to establish greener supply chains.

Case Study: Lessons from Toyota’s Supply Chain

Toyota’s supply chain is often regarded as a benchmark in efficiency. The company pioneered the JIT manufacturing approach, which minimizes waste and reduces inventory costs. However, even Toyota faced challenges during the semiconductor shortage, highlighting the importance of balancing efficiency with resilience.

The Role of Stakeholders in the Supply Chain

1. Suppliers

Suppliers are the backbone of the automotive supply chain. Tier 1 suppliers work closely with OEMs to deliver high-value components, while Tier 2 suppliers provide raw materials and sub-components.

2. OEMs

OEMs are responsible for assembling vehicles and managing supplier relationships. They play a central role in aligning production schedules with market demand.

3. Logistics Providers

Efficient transportation and warehousing are critical for timely deliveries. Innovations like autonomous trucks and drones are being explored to enhance logistics operations.

4. Dealerships

As the final link, dealerships ensure vehicles reach consumers. The rise of online sales channels is reshaping traditional dealership models.

Key Metrics for Supply Chain Performance

- Lead Time: The time taken from order placement to delivery.

- Inventory Turnover: A measure of how efficiently inventory is managed.

- On-Time Delivery Rate: The percentage of deliveries made within the promised timeframe.

- Carbon Footprint: The environmental impact of supply chain activities.

Strategies for Building Resilient Supply Chains

1. Diversification

Relying on a single supplier or region can be risky. Diversifying sourcing options can mitigate disruptions.

2. Collaboration

Strong partnerships between suppliers, OEMs, and logistics providers foster better communication and problem-solving.

3. Investing in Technology

Digital tools enhance visibility and enable real-time decision-making, reducing the likelihood of bottlenecks.

4. Sustainability Integration

Incorporating green practices not only meets regulatory requirements but also builds brand reputation among eco-conscious consumers.

The Road Ahead for Automotive Supply Chains

The automotive supply chain is poised for significant transformation. As the industry embraces electric vehicles, autonomous technology, and sustainability goals, supply chain strategies must adapt. Companies that invest in innovation, foster collaboration, and prioritize resilience will gain a competitive edge.

External factors like geopolitical shifts and environmental concerns will continue to shape the future of supply chains. However, with proactive measures and technological advancements, the industry can navigate these challenges effectively.

Conclusion

Demystifying the automotive supply chain reveals a world of complexity and interdependence. From sourcing raw materials to delivering finished vehicles, each stage plays a vital role in the industry’s success. While challenges like disruptions and rising costs persist, innovations such as digital transformation and sustainability initiatives offer a promising future.

Understanding and improving the automotive supply chain is not just a priority for industry players but also an essential step toward creating a more sustainable and efficient global economy.

For You

View AllFind out whether an SUV or a sedan is the better choice for your lifestyle. Compare space, performance, and efficiency now!

Mia Wilson

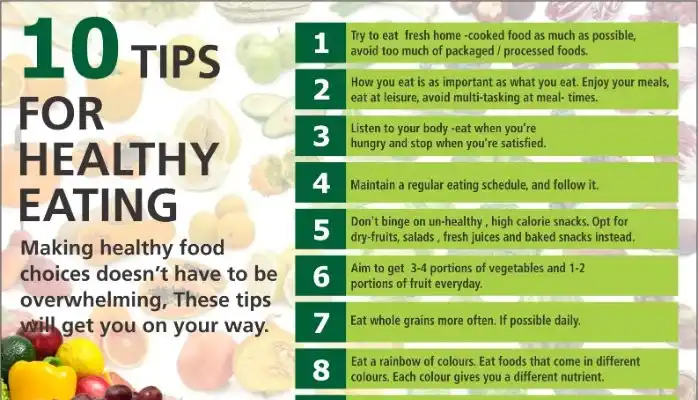

Discover the importance of health education in promoting wellness and preventing diseases. Start your journey to health today!

Mia Wilson

Get insights into VPS hosting prices and how to choose an affordable plan.

Mia Wilson

Save money while traveling with these 10 genius budget travel hacks. Explore the world without emptying your wallet!

Mia Wilson

Dive into special education, its purpose, and how it supports students with unique needs. Learn how it changes lives!

Mia Wilson

Learn why physical education is essential for health, academics, and personal growth. Get inspired to stay active!

Mia Wilson

Health

Education

View All

June 1, 2025

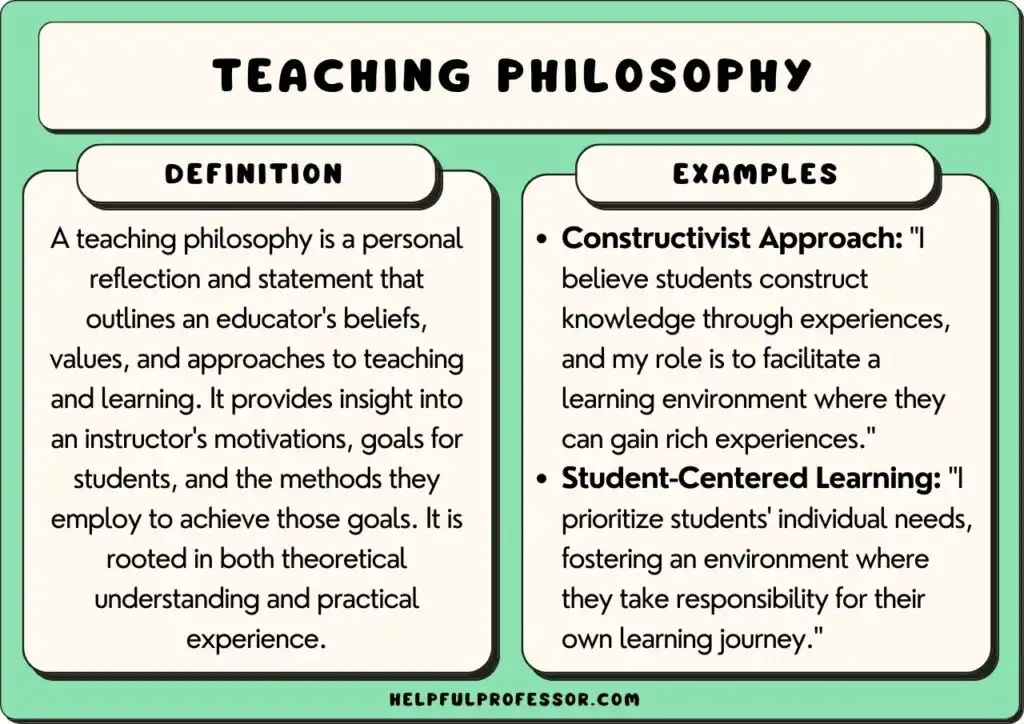

What Is Your Philosophy of Education?

Reflect on your philosophy of education, its core values, and how it influences teaching and learning practices. Discover your approach today!

April 14, 2025

What Is Physical Education? Explained!

Discover the importance of physical education, its benefits, and why it's crucial for overall development. Learn more now!

April 19, 2025

What Is Higher Education?

Understand higher education, its benefits, and how it shapes future opportunities. Explore your potential now!